If you’ve ever dealt with shipping errors, chargebacks, or frustrated customers asking for more details about what’s in their delivery — you’re not alone. For many warehouse and manufacturing operations, keeping track of what’s actually going into each box or onto each pallet can be a constant challenge, especially when orders move quickly and teams are stretched thin.

What’s making this even tougher is that customers are starting to expect more than just a basic packing list. Many now want detailed shipment data tied to each individual carton or container, so they can quickly confirm what arrived without digging through paperwork. The good news? There’s an effective way to meet those expectations, and it’s called carton-level tracking (or serialization). By merely adding a unique barcode to every carton and scanning it as part of your shipping workflow this process can dramatically reduce mistakes, improve accuracy, and protect your operation from costly penalties.

Here’s why serialization is so critical in today’s shipping operations, and what you’re risking by putting it off.

Avoid Costly Penalties for Shipping Mistakes

Shipping errors don’t just lead to customer frustration, they often come with financial penalties. Many manufacturers and retailers charge suppliers for late, inaccurate, or incomplete shipments. Without serialization, it’s difficult to pinpoint exactly which cartons were shipped and verify the contents against the order in real time.

By assigning a unique, trackable serial number to every carton or pallet, your shipping team can validate exactly what’s being picked, packed, and shipped. This dramatically reduces the risk of mistakes, ensures compliance with customer requirements, and protects your bottom line.

Meet Customer Requirements for Serialized ASNs

One of the fastest-growing demands in manufacturing and distribution is the requirement for serialized Advanced Shipping Notices (ASNs) through EDI (Electronic Data Interchange). In industries like automotive, your customers don’t just want to know what you’re sending, they want to know the specific serial numbers of each carton or container in the shipment before it arrives.

With serialization, you can used a barcode scanner or rugged mobile computer to scan each carton’s unique identifier as it’s picked and packed, then transmit that information via your ASN. When the customer receives the shipment, all they have to do is scan those same serial numbers to quickly confirm that what they received matches what you sent. This improves receiving speed and accuracy, strengthens your supplier relationship, and often leads to quicker invoice approval and (hopefully) payment.

Improve Employee Accountability and Process Accuracy

Barcode serialization isn’t just about data, it’s a powerful tool for enforcing operational discipline and preventing shortcuts on the floor.

Without serialization, it’s too easy for a worker to grab a stack of cartons, scan the first one ten times, and move on. That kind of behavior can lead to serious inventory discrepancies, order errors, and missed FIFO (First In, First Out) requirements.

Serialization requires workers to scan a unique number on every carton, which means:

- You can validate that the correct item is picked and shipped.

- FIFO picking is enforced, ensuring older inventory is moved out first.

- Shortcuts and scan workarounds are prevented, protecting the integrity of your data.

It’s a simple, effective way to police processes without adding extra layers of supervision.

Simplify Pallet Consolidation and Master Labeling

If your operation regularly ships full pallets of product, serialization makes pallet management far more efficient. By pre-configuring which serialized cartons belong on a pallet, you can assign a master label to that pallet.

At shipping time, your team only needs to scan the master label to record the shipment, and your system already knows which serialized cartons are included. This speeds up the shipping process while maintaining full traceability; a major advantage in high-volume, fast-paced environments.

Deliver More Detailed, Accurate Packing Lists

Another frequent customer request is for more detail on packing lists; especially in industries where products may come from different production lots or manufacturing runs.

With serialization, you can easily capture lot numbers, production dates, or other key data tied to each carton’s serial number. That information can then be automatically added to your packing lists, giving customers clear, accurate shipment details and improving their inventory management processes.

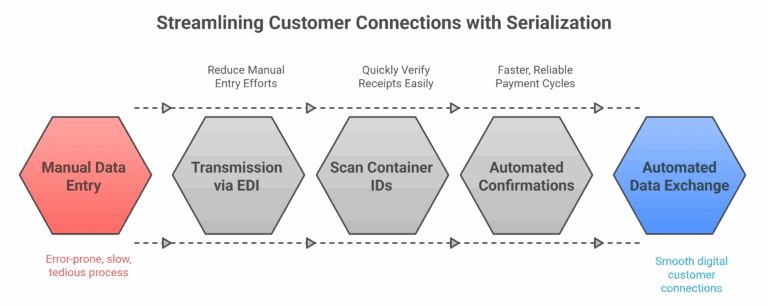

Get Ready for Faster, Easier Connections with Your Customers

As more manufacturers and distributors move toward automated, integrated supply chains, having serialized data available in your shipping process is a critical first step. Serialization enables:

- Transmission of serialized ASNs via EDI, reducing manual entry on both ends.

- Quicker verification of receipts on the customer side, since they can scan container IDs on arrival and match them to your ASN.

- Faster, more reliable invoicing and payment cycles, since shipments and receipts are confirmed automatically and consistently.

Serialization isn’t just a shipping tool — it’s a long-term operational strategy that positions your business for smoother digital connections with customers and supply chain partners.

Barcode serialization is no longer reserved for highly regulated industries. It’s a practical, valuable tool for any warehouse or manufacturing operation looking to reduce shipping errors, avoid penalties, meet customer demands, and improve operational accountability.

If your shipping department isn’t serializing its barcodes yet, now is the time to make the move. Integrated Manufacturing Systems (IMS) can help you develop a serialization strategy that integrates with your existing workflows, barcode labeling systems, and shipping applications, giving you the accuracy, traceability, and operational confidence you need to compete and grow.

Contact us today to learn more about how serialization can improve your shipping operation.